Digital Factory Solutions

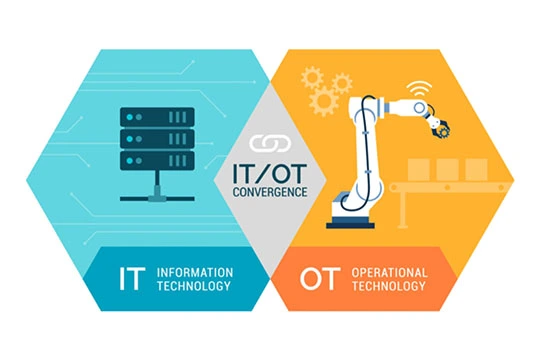

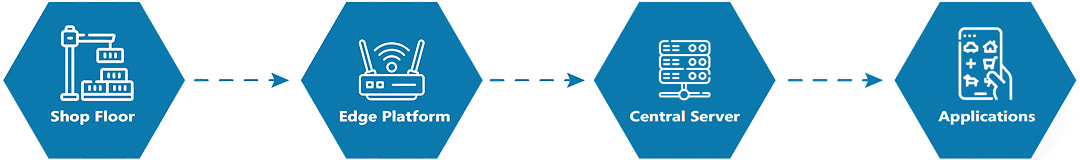

How IoT Systems Works?

Customised Dashboard

- Process Parameters

- Production - Plan Vs Actual

- Machine Downtime(OEE)

- Plant Health

- Key Performance Indicators

- Live Trends

Customize Reports

- Utility Summary Report

- Machine Performance Report

- Condition Based Monitoring Report

- Production Report

- Operator Performance Report

- Machine Downtime Report

Alerts & Notifications

- All KPI Deviations

(High/Low or On/Off) - Push Notifications on Android & iOS Devices

- Email Alerts

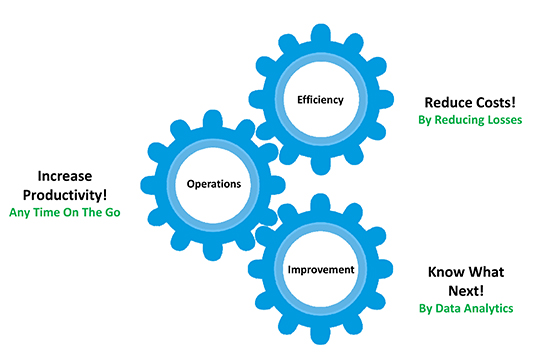

Benefits

Over existing System

- Precise hour/slot wise production to track hourly performance

- Paperless work (minimal operator intervention) with history for more than 2 years….in current system paper logs are scrapped.

Precise Action plan through Root Cause Analysis

- Pi chart indicating Quality/Productivity/Availability loss highlighting significant areas of improvement.

Operator performance report

- With supervisor and machine name in same report.

Downtime calculation

- Actual downtime values against planned break times.

Maintenance

- Diagnosis – pinpointing the failure through alerts, On-The-Go.

- Prognosis – gauging the parameter behavior and informing users in advance.

- Better communication between cross functions because of paperless methods.

Improvement of system

- Understanding the failures and its pattern by knowing the history of the machine maintenance.

- Help in making future action plan repair/replacement/upgrade of assets.

IoT for Organization

- Traceability of all process, material and people related variable for every wheel shipped out for root cause analysis

- Cost optimization using benchmarking of energy consumption across all sections.

- Productivity analysis and improvement

- Reduce overall maintenance costs up to 30%

- Eliminate breakdowns up to 70%